As technological advancements and industrial demands grow, the need for high-performance materials has never been more critical. 304 stainless steel, one of the most widely used stainless steels on the market, is renowned for its excellent corrosion resistance and durability, making it indispensable across various industries. From food processing and kitchen utensils to medical devices and architectural frameworks, the applications of 304 stainless steel are extensive and impactful.

Key Components and Their Functions

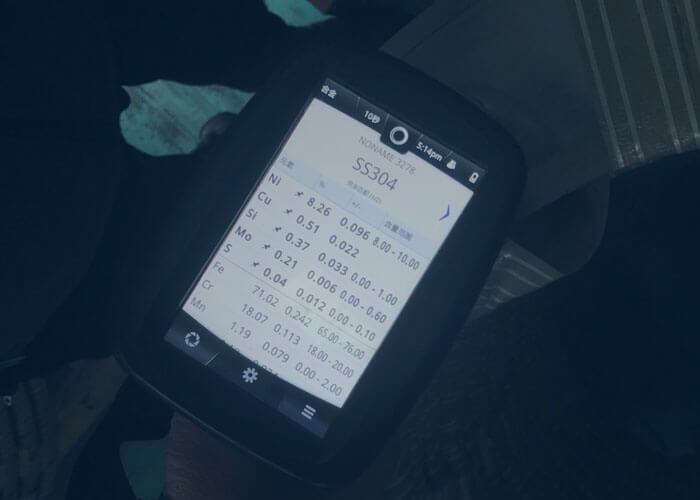

The primary components of 304 stainless steel include 18-20% chromium and 8-10.5% nickel. These elements are crucial for the alloy’s exceptional corrosion resistance. Chromium helps form a natural oxide layer on the material's surface, a passive film that protects the steel from further corrosion. Nickel enhances the overall structure of the stainless steel, improving its stability and durability in diverse environments.

Additionally, 304 stainless steel contains a small amount of carbon (up to 0.08%), which enhances the steel's strength. However, excessive carbon can affect the corrosion resistance at weld points. Other elements such as manganese, silicon, phosphorus, and sulfur are present in smaller quantities, each optimizing the alloy’s mechanical and processing properties.

Industry Applications and Outlook

304 stainless steel is crucial in the food and beverage industry due to its corrosion resistance, ease of cleaning, and maintenance simplicity. It is used to manufacture various containers, pipelines, and brewery equipment. In the medical sector, its hygienic properties make it suitable for surgical instruments and medical devices, ensuring patient safety and equipment longevity.

The construction industry also heavily utilizes 304 stainless steel as structural and decorative material, especially in environments prone to high corrosion, such as coastal cities or chemical processing areas. Additionally, its application in the automotive industry is growing, used in producing durable and aesthetically pleasing exterior components and critical performance parts.

Future Trends

As technology evolves and market demands diversify, 304 stainless steel may face more challenges in material innovation to adapt to harsher application environments. Additionally, the industry's demand for environmentally friendly and high-performance materials has spurred research into alternatives to 304 stainless steel, such as new stainless steel types with additional corrosion-resistant elements.

304 stainless steel continues to play a vital role globally, proving indispensable in industrial development. With ongoing advancements and innovations, it is expected that 304 stainless steel will continue to evolve, meeting higher technical standards and broader application needs.