Hot Rolled

Thickness: 3mm-200mm

Width: 1500/1800/2000mm or as your request

Length: 2438/3000/6000mm or as your request

Edge: Slit, Mill;

Surface :No.1, 2D, 2B

Cold Rolled

Thickness: 0.3-6.0mm

Width: 1000/1219/1250/1500mm or as your request

Length: 2000/2438/3000/6000mm or as your request

Edge: Slit,Mill;

Surface: 2B, BA, No.4, HL etc

Stainless steel plates are widely used in various industries due to their remarkable properties, including corrosion resistance, high strength, and aesthetic appeal. These plates are categorized based on their manufacturing processes into hot rolled and cold rolled plates, each having distinct characteristics and applications.

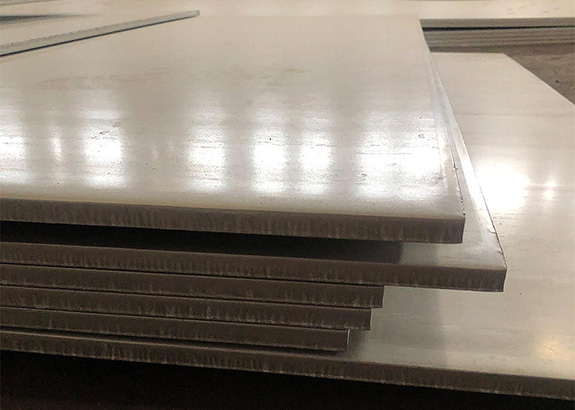

1.Hot Rolled Stainless Steel Plates

Hot rolled stainless steel plates are made by heating the steel above its recrystallization temperature and rolling it into the desired thickness. This process results in plates with a rough surface finish and a wider range of thicknesses, making them ideal for applications where precision and surface smoothness are not critical.

Thickness Range: 3 mm to 200 mm

Common Grades: 304, 316, 321, 310S, 430

Surface Finishes: No.1, 2D, 2B

2. Cold Rolled Stainless Steel Plates

Cold rolled stainless steel plates are produced by rolling the steel at room temperature, which increases its strength and improves surface finish. These plates are characterized by their smooth, shiny appearance and precision dimensions, making them suitable for applications requiring high aesthetic and dimensional accuracy.

Thickness Range: 0.3 mm to 6 mm

Common Grades: 304, 316, 321, 430

Surface Finishes: 2B, BA, No.4, HL

Common Stainless Steel Grades

304 Stainless Steel: Known for its excellent corrosion resistance and formability, widely used in kitchen equipment, chemical processing, and architectural applications.

316 Stainless Steel: Contains molybdenum for enhanced corrosion resistance, especially against chlorides and marine environments, making it ideal for marine equipment, pharmaceutical manufacturing, and medical devices.

321 Stainless Steel: Stabilized with titanium, offering improved resistance to intergranular corrosion, commonly used in aerospace and high-temperature applications.

310S Stainless Steel: High chromium and nickel content provides excellent high-temperature resistance, suitable for furnace parts and heat treatment equipment.

430 Stainless Steel: Ferritic stainless steel with good corrosion resistance and formability, used in automotive trim, appliances, and kitchen utensils.

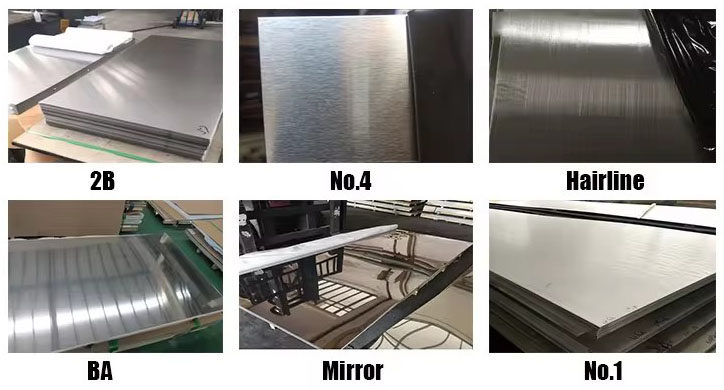

Surface Finishes

No.1 Finish: Rough, dull surface obtained through hot rolling and annealing, typically used where appearance is not a primary concern.

2D Finish: Dull finish produced by cold rolling, annealing, and descaling, suitable for industrial applications.

2B Finish: Smooth, reflective finish achieved by cold rolling, annealing, and light skin passing, commonly used for general purposes.

BA (Bright Annealed) Finish: Highly reflective, mirror-like finish produced by bright annealing in a controlled atmosphere.

No.4 Finish: Brushed finish with fine polishing lines, often used in kitchen equipment and architectural applications.

HL (Hairline) Finish: Smooth, continuous polishing lines, giving a modern aesthetic for decorative uses.

For more detailed information on specific grades and finishes, or to find the right stainless steel plate for your project, contact our team of experts.

We are factory and we can provide competitive price.

Of course, we welcome customers from all over the world to visit our factory.

Of course, we can provide customers with free samples and express shipping service to all over of the world.

Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

Usually our lead time is 7 working days, if you need this order in a hurry, pls feel free to let me know, I’ll negotiate with our production team and put your order as priority.

Yes,if you have your own design , we can produce according to your specification and drawing.

Lorem ipsum is a dummy text it will use for subtitle here