Grade: A36, A572, A516, A283, A285, A387,A514 etc.

Thickness: 0.5mm - 200mm

Width: 1000mm - 4000mm

Length: 2000mm - 12000mm

Standards: ASTM,EN,JIS,DIN, etc

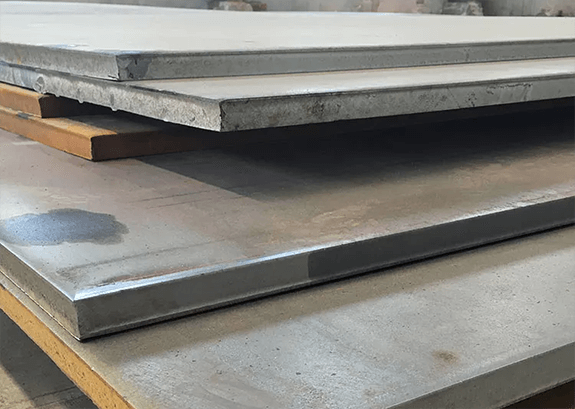

Carbon Steel Plate

Carbon steel plates are versatile and fundamental components used across various sectors, including construction, industrial machinery, shipbuilding, and infrastructure projects.

Overview of Carbon Steel Plate

Carbon steel plates are flat, rectangular sheets of carbon steel that come in varying thicknesses. This material is known for its strength and durability, making it a popular choice for heavy-duty applications. The composition of carbon steel involves iron and carbon, with proportions of carbon ranging from 0.05% to 2.1%, which affects the steel's overall strength and ductility.

Product | Carbon Steel Plate |

| Material | Q235, Q345, A36, A572, S235, S355, etc. |

| Thickness | 0.5mm - 200mm (customizable as per requirements) |

| Width | 1000mm - 4000mm (customizable as per requirements) |

| Length | 2000mm - 12000mm (customizable as per requirements) |

| Standard | ASTM, ASME, EN, JIS, DIN, GB, etc. |

| Surface | Hot Rolled, Cold Rolled, Oiled, Galvanized, etc. |

| Tensile Strength | 400 - 550 MPa (depends on the specific material) |

| Yield Strength | 250 - 355 MPa (depends on the specific material) |

The allowable deviation of the thickness

| Nominal thickness (mm) | Thickness tolerance (mm) | Width direction after slicing | Rolling direction after slicing Thickness deviation (mm) |

| >1.5-2.6 | ±0.10 | ≤0.05 | ≤0.05 |

| >2.6-3.0 | ±0.12 | ≤0.05 | ≤0.05 |

| >3.0-4.0 | -0.17~+0.12 | ≤0.05 | ≤0.05 |

Mechanical properties

| Nominal thickness | Yield strength (Mpa) | Tensile strength (Mpa) | Elongation A50mm% | 180 degree bending test |

| >1.5-2.5 | ≤290 | ≥310 | ≥38 | D=0a |

| >2.5-3.0 | ≤290 | ≥300 | ≥38 | D=0a |

| >3.0-4.0 | ≤290 | ≥300 | ≥40 | D=1/2a |

Key Features:

Strength and Toughness: Carbon steel plates are known for their high strength and toughness, which make them suitable for structural applications where durability is crucial.

Weldability and Machinability: These plates can be easily welded and shaped, facilitating their use in manufacturing complex structures and machinery.

Versatility: Available in several grades that vary in strength and durability, carbon steel plates can be tailored to specific applications through controlled additions of alloys.

Specifications:

Carbon steel plates typically follow certain standards that ensure their quality and suitability for specific applications, such as ASTM, EN, or JIS. These standards define the mechanical properties like tensile strength, yield strength, and elongation, as well as dimensions including thickness, width, and length.

Common Applications:

Construction: Used in the building of bridges, buildings, and other structures due to their ability to withstand environmental and mechanical stresses.

Shipbuilding: Essential for constructing ship bodies and structural components because of their capacity to resist corrosion and withstand high pressures.

Pressure Vessels: Ideal for manufacturing storage tanks and boilers as they can handle high pressure without deforming.

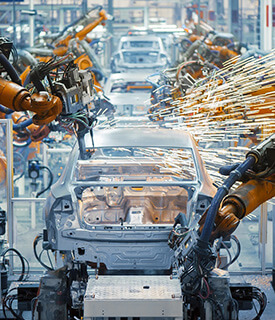

Machinery Manufacturing: Used in the creation of machinery parts that require robustness and resistance to wear and tear.

Importance:

The widespread use of carbon steel plates underscores their importance in industrial and construction settings. Their adaptability allows engineers and builders to use them in environments that demand high strength and durability, contributing significantly to modern infrastructure and technological advancements.

In summary, carbon steel plates are integral materials with broad applications across various industries due to their strength, versatility, and machinability. They play a critical role in supporting modern industrial practices and building the structures of the modern world.

We are factory and we can provide competitive price.

Of course, we welcome customers from all over the world to visit our factory.

Of course, we can provide customers with free samples and express shipping service to all over of the world.

Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

Usually our lead time is 7 working days, if you need this order in a hurry, pls feel free to let me know, I’ll negotiate with our production team and put your order as priority.

Yes,if you have your own design , we can produce according to your specification and drawing.

Lorem ipsum is a dummy text it will use for subtitle here