The main processes of aluminum profile surface treatment involve multiple steps to improve their appearance quality and corrosion resistance. Below will introduce the main aluminum profile surface processing process.

1. Pre -processing: This is the first step in the entire surface treatment process. It aims to remove oil, dust and impurities on the surface of aluminum profile. Common pre -processing methods include alkali washing, pickling, mechanical cleaning, etc. Alkaline washing can be used to remove organic and inorganic impurities on the surface of aluminum surface. Purmium uses acid solution to remove the oxidation layer and other impure substances on the surface.

2. Anti -corrosion treatment: Aluminum profiles are easily affected by oxidation and corrosion, so anti -corrosion treatment is important. The most commonly used method is to use the aluminum profiles after washing or alkali for oxygen removal to remove the oxidation layer, and then form a protective film on the surface. This can be implemented by soaking in a solution of nitric acid after the pickled aluminum profile.

3. Ceramic spraying: Ceramic spraying is a common surface treatment method, which aims to provide better abrasion resistance and corrosion resistance. This method forms a protective layer with good physical and chemical properties by spraying a special layer of ceramic coating on the surface of the aluminum profile. This ceramic coating can improve the hardness and abrasion resistance of aluminum profiles and extend its service life.

4. Electric Painting: Electric Painting is a coating method that is suitable for coating of aluminum profiles. This method By immersed aluminum profiles into an electrophoretic slot with coating particles, the coating particles are uniformly deposited on the surface of the aluminum profile with the principle of electrical sword. Then use drying and solidification steps to form a solid coating. Electric sword can provide excellent corrosion performance and appearance quality.

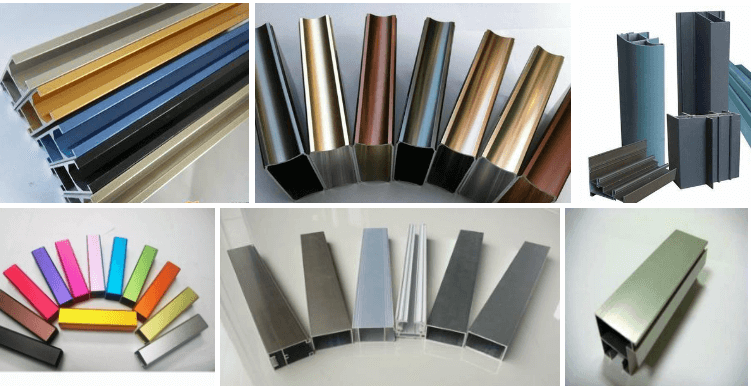

5. anode oxidation: anode oxidation is a commonly used surface treatment method, suitable for aluminum profiles. This process improves its corrosion resistance and appearance quality by forming oxidation layers on the surface of aluminum profiles. During the anode oxidation, aluminum profiles are used as anode, and electrolytic is processed in an acidic solution. By controlling the current density and processing time, you can obtain a different thickness and color oxidation layer.