Laser cutting offers significant advantages over other 2D processing methods when working with stainless steel. The technology involves no force or distortion, so it does not induce any work hardening. Laser cutting, when performed under optimal conditions, produces fused, fairly smooth edges that rarely need post-processing. Cuts as deep as 100 mm are possible in a single pass which allows fast processing of large items.

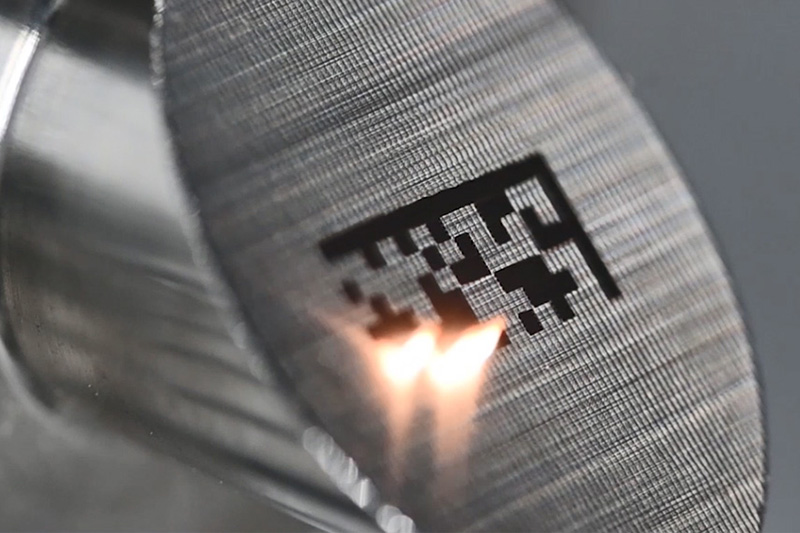

Laser marking of stainless steel comes in two forms: straightforward ablation and laser annealing. Laser ablation is the process by which material is vaporized and removed. Laser annealing, on the other hand, is where the chromium oxide surface is largely undisturbed; instead, the metal beneath is annealed or melted and a limited amount of oxidation takes place below the outer oxide film. The latter method makes cleaner markings but it requires considerable skill to do it without ablating some material away. The low (highly localized) heating of the target area results in little or no distortion and staining in the wider heat-affected zone (HAZ). By contrast, rapid rotating cutter machining can alter hardness considerably around the cut zone and can result in heat distortion and discoloration over wider areas.

Laser engraving of stainless steel is possible as well, but it often results in discoloration. The engraving process destroys some of the surface oxide layers. Laser engraving is functionally identical to laser cutting. The difference is that the cut depth must be very tightly controlled to achieve good surface quality.

Laser etching is a more controlled process for stainless steel. The subsurface of unoxidized metal is annealed or melted without removing the protective oxide surface layer, which is essentially transparent to most cutting lasers. This method allows limited diffusion of oxygen through the oxide layer, staining the metal below in shades of yellow or brown depending on the intensity. This process is sometimes referred to as laser annealing.